Main Cylinders

For most of the photos on this page, you can click the image for a larger picture.

|

This is how the boards are built up. As you can see, we want the boards to exceed the diameter of the template. The pattern will be turned down to the diameter of the template on the lathe. This is the first semi circle of 4 that he will need to create. |

|

Assembling the boards needs glue, pressure and lots of clamps! You can see a completed half semi circle pattern in the background, 3 more to go. |

|

Dowels are used between the boards for additional strength. The pattern is hollow to attempt to reduce the weight (a bit!). |

|

Here's the assembled pattern for semi circle 3 |

|

The 2 halves of the motion cylinder pattern are located together ready for lifting onto the lathe. The lathe is on the right. |

|

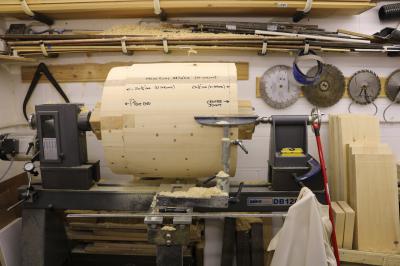

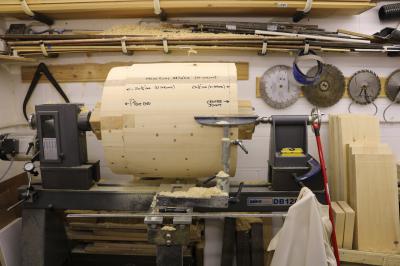

The pattern is now on the lathe ready for turning to the diameter indicated by the black line. This photo is the of the first 2 halves. |

|

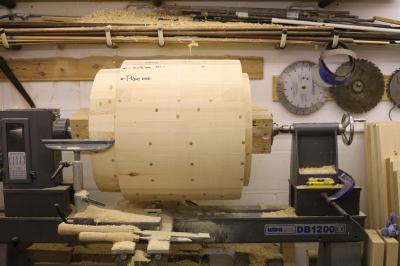

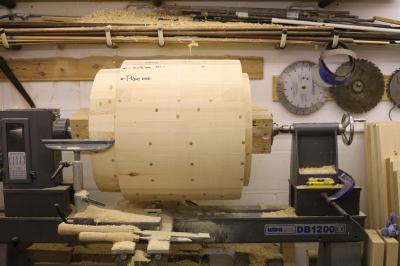

The 2 semi circles make up the second half of the motion cylinder pattern. We're now ready to start turning the outside of the pattern on the lathe. |

|

Turning has started on the first half of the motion cylinder pattern. Tony says

"Before I started turning at all I cleaned down to the marked circle with a power plane. Moving on to the turning, I started at low speed with a large roughing gouge slowly increasing speed up to around 400 RPM.

Timber cuts much better at higher speeds but I was mindful of the weight of the rotating mass. There are a number of different types and densities passing the tool with plywood and dowels as part of the mix so it always feels a bit weird. Once I'd got it down to a cylinder, I clocked the tail-stock revolving centre (with the dial gauge in the bottom left of the photo) as I did notice that the blank, when at rest, was slightly heavier at one side. Although yellow pine is a fine wood it does differ in density. The rotating blank is slightly out of balance and my rotating centre has 3.5 thou bearing play when turning with this mass but I'm not really bothered about 7 thou when working to 1/32". |

|

Turning continues. On the right hand hand end of the cylinder is the start of joint which will mate with a socket that Tony will turn on the second half of the pattern. On the left is the start of the 'core print' which will be the same diameter of the hole left through the cylinder after casting. The core print, whilst being part of the pattern will not be seen on the finished casting. Tony reports that the turning generates a lot of sawdust! |

|

I asked Tony to explain what the terms 'cores' and 'prints' meant in the pattern making world. He says "Cores and prints are the complicated parts of the pattern. Basically, the external pattern shape resembles the finished casting but the pattern is made 'solid' for the first parts of the moulding process. What then has to be added are solid cores of core moulding sand which form the 'holes' in the final casting - in this case, the hole that will be the cylinder where the piston will run. To hold these cores in position, depressions in the sand locate made by 'prints' locate specifically these hard sand cores in position. The generally accepted colour code for core prints is black so I have painted core print on the left hand half of the cylinder to identify a print. There will be one at the right hand end of the right hand end of the cylinder pattern. These prints are not part of the finished casting. The attached photo shows for general interest a core print. This particular print is the same diameter of the hole in the cylinder. When I demount this section at some time I will remove the square section of timber and finish off the print, in the meantime they will be used for handling purposes when I put back the lifting pins. |